Automated Guided Vehicle (AGV) systems are revolutionizing the material handling industry by increasing efficiency, reducing labor costs, and improving safety. One of the key components of AGV systems is the power battery, which is responsible for providing the energy needed to move materials from one location to another.

In recent years, advances in power battery technology have led to the development of AGV power batteries with higher energy density, longer life cycles, and faster charging times. These improvements have made AGV systems even more efficient and cost-effective, and have helped to increase their adoption in various industries, including manufacturing, warehousing, and distribution.

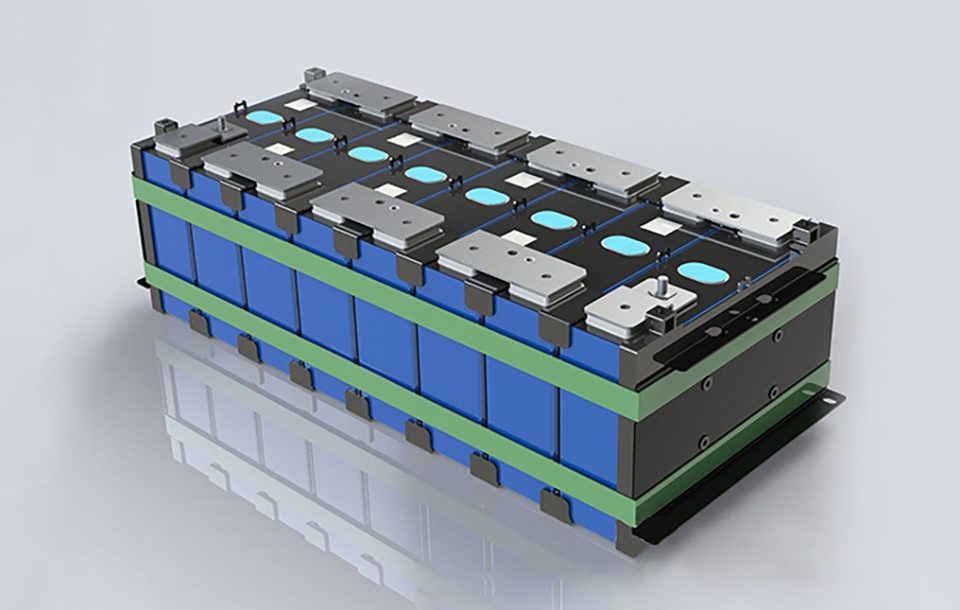

There are several types of power batteries commonly used in AGV systems, including lead-acid batteries, lithium-ion batteries, and nickel-metal Hydride (NiMH) batteries. Lead-acid batteries are the most commonly used power batteries in AGV systems due to their low cost and long history of reliability. However, lithium-ion batteries are becoming increasingly popular due to their high energy density, which allows AGV systems to operate for longer periods of time on a single charge.

Lithium-ion batteries are also lighter and more compact than lead-acid batteries, which makes them easier to install and maintain in AGV systems. Additionally, they are less prone to sulfation, which can cause lead-acid batteries to lose capacity over time.

NiMH batteries are another type of power battery that is gaining popularity in AGV systems. Like lithium-ion batteries, NiMH batteries are lighter and more compact than lead-acid batteries, and they offer longer life cycles and faster charging times. However, NiMH batteries are generally more expensive than lead-acid and lithium-ion batteries, which makes them less popular in cost-sensitive industries.

Regardless of the type of power battery used, it is important to properly maintain AGV power batteries to ensure that they last as long as possible. Proper maintenance includes regularly checking the battery’s charge level, ensuring that the battery is kept clean and dry, and avoiding overcharging or deep discharging the battery.

In conclusion, AGV power batteries play a critical role in the efficiency and success of material handling operations. With advances in power battery technology, AGV systems are becoming increasingly efficient, cost-effective, and reliable, making them a key tool for businesses looking to improve their material handling operations.