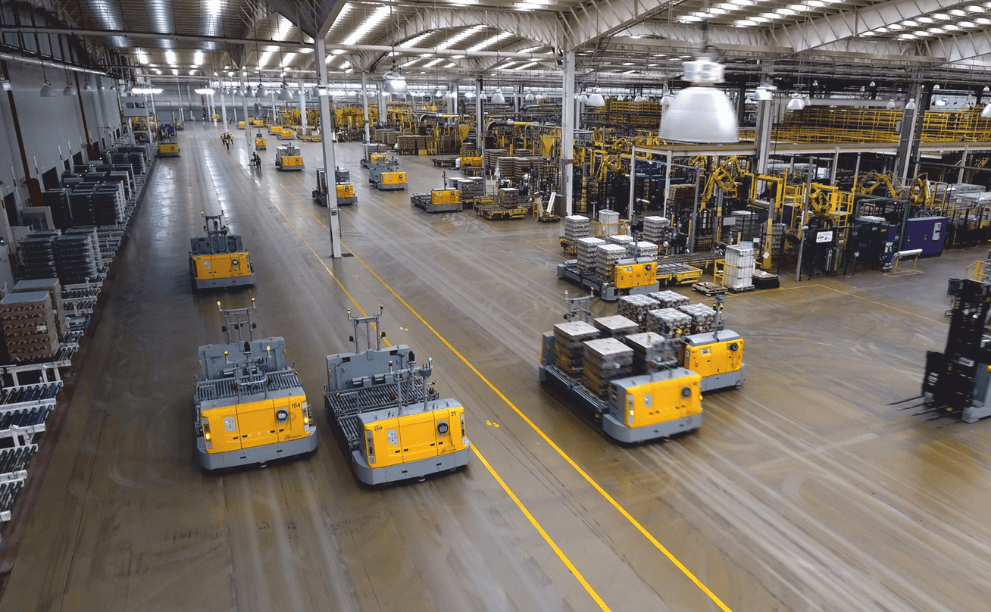

Los vehículos de guiado automático (AGV) están transformando las industrias al agilizar las operaciones, mejorar la productividad y minimizar los costes de mano de obra. Ya se utilicen en almacenes, plantas de fabricación o centros de distribución, los AGV dependen en gran medida de sus sistemas de baterías para funcionar con eficacia. Como tal, el mantenimiento adecuado de la batería es fundamental para maximizar tanto el rendimiento como la vida útil de estos componentes esenciales.

En este artículo, analizaremos los consejos de mantenimiento esenciales para Baterías para AGVcentrándose en cómo mejorar su eficiencia, reducir los costes operativos y garantizar su longevidad. Siguiendo estas directrices, puede mejorar significativamente la fiabilidad de su flota de AGV y evitar costosos tiempos de inactividad.

Sistemas de baterías AGV

Antes de entrar en los consejos de mantenimiento, es importante conocer los tipos de baterías que se utilizan habitualmente en los vehículos AGV y su funcionamiento. Los tipos de baterías más comunes para AGV son plomo-ácido y ión-litio (Li-ion) baterías, cada una de las cuales ofrece ventajas y retos distintos.

-

Baterías de plomo-ácido son tradicionales y rentables, pero requieren más mantenimiento, como la reposición periódica de agua y la limpieza. Son más voluminosas y pesadas que las baterías de iones de litio.

-

Baterías de iones de litio se han hecho cada vez más populares por su tamaño compacto, su capacidad de carga más rápida y sus mínimos requisitos de mantenimiento. Sin embargo, son más caras de entrada, aunque ofrecen importantes ahorros a largo plazo por la reducción de los costes de mantenimiento.

Tanto si utilizas baterías de plomo-ácido como de iones de litio, un cuidado adecuado es esencial para mantener su eficiencia y maximizar su vida útil operativa.

1. Supervise regularmente los niveles de carga y tensión de la batería

Tanto para las baterías de plomo-ácido como para las de iones de litio, es esencial controlar periódicamente los niveles de carga y tensión. Los AGV dependen de una alimentación constante, y las fluctuaciones en los niveles de la batería pueden provocar un rendimiento inferior al óptimo, una menor productividad y ciclos de recarga más frecuentes. Esto es lo que debe tener en cuenta:

-

Baterías de plomo-ácido: Deben recargarse cuando la tensión desciende hasta aproximadamente el 50-60% de la carga completa. La descarga excesiva de una batería de plomo-ácido puede provocar daños y una reducción significativa de su vida útil.

-

Baterías de iones de litio: Estas baterías suelen funcionar de forma más eficiente, pero sigue siendo esencial asegurarse de que no se cargan o descargan hasta sus extremos con frecuencia. Normalmente, las baterías de iones de litio deben cargarse cuando alcanzan los 20% y descargarse antes de que lleguen a los 90-95% para que su estado sea óptimo.

El uso de sistemas de gestión de baterías (BMS) puede ayudar a realizar un seguimiento automático de estos niveles, proporcionando datos en tiempo real para garantizar que su flota de AGV funcione al máximo rendimiento.

2. Limpie e inspeccione regularmente los bornes de la batería

Los terminales de las baterías pueden acumular suciedad, polvo y corrosión con el tiempo, especialmente en entornos con mucha humedad o expuestos a productos químicos. Esta acumulación puede obstaculizar el flujo de electricidad, provocando ineficiencias y posibles fallos de la batería.

Para evitar la corrosión, limpie regularmente los bornes de la batería con una solución de bicarbonato sódico y agua. Asegúrese de desconectar la batería antes de limpiarla y utilice un cepillo suave para frotar suavemente los terminales. Después, aplique una fina capa de vaselina o un protector de terminales de batería para evitar la corrosión en el futuro.

La inspección periódica de los terminales de la batería también puede ayudar a detectar problemas a tiempo, como conexiones sueltas o cables deshilachados, que podrían provocar problemas de rendimiento o incluso el fallo del sistema.

3. Garantizar prácticas de carga adecuadas

La carga es uno de los aspectos más críticos de Batería de AGV mantenimiento. Las malas prácticas de carga pueden acortar la vida útil de la batería y provocar averías frecuentes. He aquí algunas buenas prácticas:

-

Evitar la sobrecarga o la infracarga: Una carga excesiva puede provocar la acumulación de calor y dañar los componentes internos de la batería, mientras que una carga insuficiente puede dar lugar a ciclos incompletos y reducir la capacidad total. Siga siempre las recomendaciones del fabricante para los protocolos de carga.

-

Utiliza cargadores compatibles: Utilice siempre cargadores compatibles con su tipo de batería, ya sea de plomo-ácido o de iones de litio. Los cargadores incorrectos pueden afectar al rendimiento y la seguridad de su batería AGV.

-

Permitir una refrigeración adecuada: La carga genera calor, especialmente en operaciones de alta intensidad. Asegúrese siempre de que el AGV y su estación de carga estén situados en una zona fresca y seca con buena ventilación para evitar el sobrecalentamiento durante los ciclos de carga.

-

Realizar cargas profundas periódicas: Tanto las baterías de plomo-ácido como las de iones de litio se benefician de "cargas profundas" periódicas, en las que la batería se carga completamente después de haberse descargado parcialmente. Esto ayuda a recalibrar el nivel de carga de la batería y prolonga su vida útil.

4. Control de temperatura: Protección de la batería del AGV frente a condiciones extremas

Las temperaturas extremas, ya sean frías o calientes, pueden afectar drásticamente al rendimiento y la vida útil de las baterías de los vehículos AGV. Tanto las baterías de plomo-ácido como las de iones de litio son sensibles a las fluctuaciones de temperatura. A continuación le indicamos cómo puede mitigar los problemas relacionados con la temperatura:

-

Mantener las pilas frías: Las altas temperaturas pueden hacer que las baterías se degraden más rápidamente, aumentando la frecuencia de los ciclos de recarga y reduciendo su vida útil total. En general, las baterías de los AGV deben mantenerse entre 20°C y 25°C (68°F y 77°F).

-

Aislar del frío: Las bajas temperaturas pueden reducir la capacidad de carga de las baterías. En condiciones de congelación, las baterías pueden funcionar con lentitud o no cargarse en absoluto. En tales entornos, se debe considerar la posibilidad de utilizar armarios aislados para las baterías o un almacenamiento con clima controlado para protegerlas.

Controlar la temperatura del sistema de baterías de su AGV es crucial. Algunos AGV incorporan sensores de temperatura que alertan a los operarios si la temperatura se sale del rango óptimo, lo que proporciona un enfoque proactivo para el mantenimiento de las baterías.

5. Realice comprobaciones y mantenimiento periódicos de la batería

Las baterías de los AGV, como todos los componentes, se desgastan con el tiempo. Programar revisiones periódicas de mantenimiento e inspecciones del estado de las baterías puede evitar fallos inesperados y ayudar a detectar problemas menores antes de que se conviertan en problemas graves. Las áreas clave que deben inspeccionarse son:

-

Equilibrado de celdas de batería: En las baterías de iones de litio, cada celda puede desequilibrarse con el tiempo. Si no se equilibran con regularidad, la batería perderá capacidad y se degradará más rápidamente. Las baterías de iones de litio modernas suelen incorporar un sistema de gestión de baterías (BMS) para controlar y equilibrar las celdas, pero aún así se recomienda realizar comprobaciones periódicas.

-

Envejecimiento de la batería: Tanto las baterías de plomo-ácido como las de iones de litio se degradan con el tiempo. Las baterías de plomo-ácido pueden presentar sulfatación, mientras que las baterías de iones de litio pueden experimentar una pérdida de capacidad debido a los repetidos ciclos de carga y descarga. Reconocer a tiempo los signos de envejecimiento puede ayudar a evitar tiempos de inactividad y costes innecesarios.

-

Comprobación de fugas y daños físicos: Ambos tipos de pilas pueden perder líquidos o mostrar signos de daños físicos si se manipulan mal. Incluso pequeñas grietas o daños en las carcasas de las pilas pueden comprometer su integridad y reducir su rendimiento.

6. Considere la posibilidad de cambiar a baterías de iones de litio para mejorar la eficacia del mantenimiento.

Si actualmente utiliza baterías de plomo-ácido en sus vehículos AGV, puede que haya llegado el momento de plantearse cambiar a baterías de iones de litio (Li-ion). Aunque tienen un coste inicial más elevado, las baterías de iones de litio ofrecen varias ventajas a largo plazo que pueden facilitar el mantenimiento y reducir los costes operativos:

-

Carga más rápida: Las baterías de iones de litio se cargan más rápidamente que las de plomo-ácido, lo que reduce el tiempo de inactividad de sus AGV.

-

No es necesario rellenar el depósito de agua con regularidad: A diferencia de las baterías de plomo-ácido, las baterías de iones de litio no requieren un mantenimiento regular, como el rellenado de agua o la limpieza de los terminales.

-

Mayor vida útil: Las baterías de iones de litio suelen tener una vida útil más larga que las de plomo-ácido, por lo que requieren menos sustituciones y un mantenimiento menos frecuente.

Conclusión

Mantenimiento adecuado de Baterías para AGV es esencial para garantizar un rendimiento óptimo, prolongar la vida útil de la batería y reducir los costes operativos. Si supervisa periódicamente los niveles de carga, mantiene los terminales limpios, sigue las mejores prácticas de carga, controla las temperaturas y realiza comprobaciones rutinarias del estado de las baterías, podrá maximizar la eficiencia de su flota de AGV y evitar costosos tiempos de inactividad.

Aunque las baterías de plomo-ácido siguen siendo una opción rentable, la actualización a baterías de iones de litio puede ofrecer importantes ventajas a largo plazo en términos de facilidad de mantenimiento, velocidad de carga y vida útil general. Si es proactivo en el mantenimiento de sus baterías AGV, estará invirtiendo en la eficiencia y rentabilidad futuras de sus operaciones.