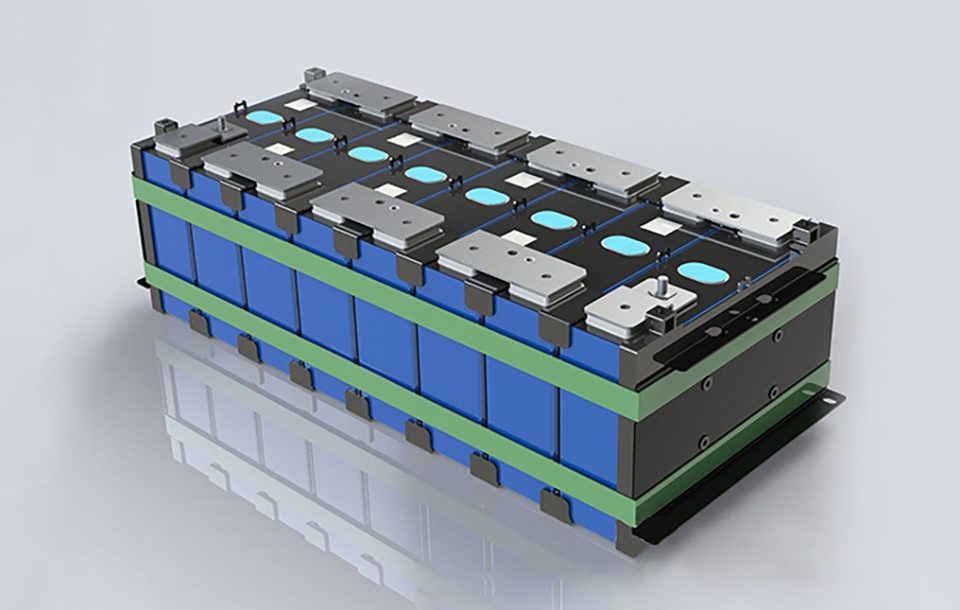

In today's rapidly evolving energy landscape, lithium batteries are increasingly becoming a key component of technologies that power everything from electric vehicles to renewable energy storage. However, the transportation of large-capacity lithium batteries, especially in international logistics, poses unique challenges due to the potential safety risks and regulatory complexities. For companies involved in the production or export of lithium batteries, understanding the proper procedures for safe and compliant transportation is crucial. This article offers a practical guide on how to safely transport large-capacity lithium batteries, addressing the essential precautions and international logistics considerations.

Understanding the Risks of Lithium Battery Transportation

Before diving into the logistics of transporting lithium batteries, it is important to first understand why these batteries pose such risks during transit. Lithium batteries, particularly those with high energy densities, can become hazardous under certain conditions. When damaged or exposed to extreme conditions like high heat or improper handling, lithium batteries may experience thermal runaway—a process in which the battery overheats, potentially leading to fire or explosion.

Due to these risks, lithium battery shipments are subject to strict regulations, particularly under the auspices of the International Air Transport Association (IATA), International Maritime Dangerous Goods (IMDG) Code, and various national transportation bodies. Ensuring compliance with these regulations is key to both safety and legal operation.

Key Considerations for Safe Transport

1. Packaging and Labeling

One of the most important aspects of safely shipping lithium batteries is the correct packaging and labeling. Lithium batteries, especially those over a certain watt-hour (Wh) rating, must be packaged in a way that prevents short circuits, physical damage, and exposure to moisture or extreme temperatures.

-

Packaging Requirements: Large-capacity lithium batteries need to be transported in strong, durable packaging that includes insulation to protect terminals and prevent short-circuiting. This often involves placing the batteries in non-conductive materials such as plastic, with protective caps on terminals. The packaging must also be clearly labeled with "Lithium Battery" stickers and the corresponding hazard symbol.

-

Labeling Compliance: Proper labeling is not just a regulatory requirement but also helps in emergencies. All packages containing lithium batteries must be marked with specific labels to inform handlers of the contents. For air transport, the “Lithium Battery Handling Label” is essential, and the UN3480 or UN3481 classification code (depending on whether the battery is contained in or packed with equipment) should be included on the outer packaging.

2. Choosing the Right Transportation Mode

Selecting the appropriate transportation mode—whether by air, sea, or land—can significantly impact the safety and cost-efficiency of lithium battery shipping.

-

Air Transport: Lithium batteries transported by air are subject to the most stringent regulations. Airlines often have specific weight and size restrictions for lithium battery shipments. The IATA Dangerous Goods Regulations (DGR) classify lithium batteries as dangerous goods, requiring compliance with special packaging and handling procedures. Large batteries may require special arrangements for cargo flights rather than being included in passenger aircraft holds.

-

Sea Freight: Shipping lithium batteries by sea is often considered safer than air freight because of the lower risk of thermal runaway in the event of an incident. However, sea freight also comes with its own set of regulations, primarily governed by the IMDG Code. Although sea freight is more affordable than air transport, it requires additional time and coordination, especially for long-distance exports.

-

Ground Transportation: For land transport, lithium batteries are generally subject to less strict regulations, but companies must still comply with local safety rules. In the United States, for instance, the Department of Transportation (DOT) oversees the transportation of lithium batteries by road and rail, which involves labeling and other precautionary measures.

3. Documentation and Compliance

The shipment of lithium batteries requires comprehensive documentation to ensure compliance with local and international laws. Key documents include:

-

Material Safety Data Sheet (MSDS): This document provides critical information regarding the composition of the lithium battery, including handling, storage, and emergency procedures in the event of an accident. It is required for both air and sea transport.

-

Shipper’s Declaration for Dangerous Goods: This declaration is required for air shipments and must be completed by the shipper to confirm that the lithium batteries are compliant with IATA regulations.

-

Customs Documentation: When shipping internationally, businesses must also prepare the appropriate customs documentation to avoid delays. This typically includes an export declaration, customs invoices, and proof of origin certificates.

Best Practices for Exporting Lithium Batteries

For companies involved in exporting lithium batteries, adhering to international safety standards is paramount. Here are some best practices to ensure smooth and safe logistics:

-

Partner with Experienced Freight Forwarders: Work with freight forwarders who specialize in hazardous materials, particularly lithium batteries. These experts are well-versed in international shipping regulations and can provide invaluable guidance throughout the process.

-

Stay Informed on Changing Regulations: Regulations surrounding lithium battery transport are continually evolving. Companies must stay updated with the latest rules and updates from agencies such as IATA and the IMDG, ensuring that all shipping practices are compliant.

-

Regular Safety Training for Employees: To avoid mishandling during the packing and transportation process, it's crucial to provide regular safety training for all personnel involved in the transportation of lithium batteries. This includes proper packaging, labeling, and emergency response protocols.

-

Use Track and Trace Technology: Utilizing advanced tracking technology can help businesses monitor the location and condition of their lithium battery shipments in real-time. This minimizes the risk of lost shipments and provides critical information in case of an emergency.

The Role of RICHYE in Ensuring Safe and Efficient Transportation

At RICHYE, we pride ourselves on providing high-quality lithium batteries that meet international safety and performance standards. As a trusted lithium battery manufacturer, we understand the complexities of transporting large-capacity batteries across borders. Our products are designed with the highest standards of safety and durability in mind, ensuring that our batteries remain secure during transit, even under the most challenging conditions.

Our commitment to excellence extends to every part of our operations, from battery manufacturing to logistics. We collaborate with experienced logistics partners to ensure that our products are shipped in full compliance with all regulatory requirements, helping our customers navigate the complexities of international shipping.

Conclusion

The safe transport of large-capacity lithium batteries is essential for businesses involved in the global supply chain of renewable energy products and electric vehicles. By understanding the unique challenges and following best practices—such as proper packaging, labeling, selecting the right transport mode, and staying informed about regulations—companies can ensure the safe delivery of their products while minimizing the risks associated with hazardous goods.

As the demand for lithium batteries continues to grow, ensuring a streamlined, safe, and compliant transportation process will remain crucial to supporting the global transition to cleaner, more sustainable energy solutions.