Giới thiệu: Những nguyên lý cơ bản của pin lithium sắt photphat

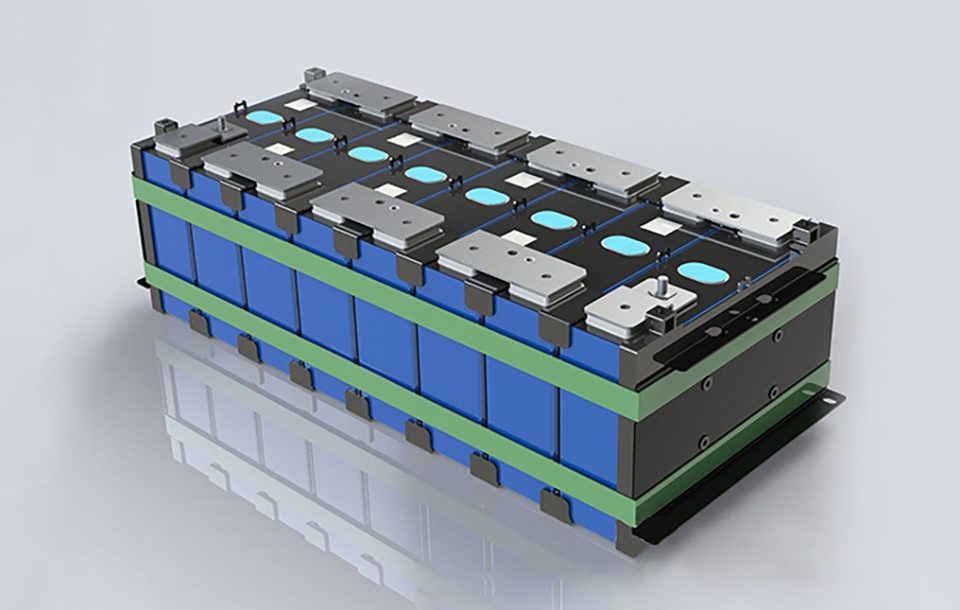

Trong bối cảnh phát triển nhanh chóng của lĩnh vực lưu trữ năng lượng, Pin lithium sắt photphat (LFP) Đã trở thành giải pháp quan trọng cho nhiều ứng dụng, từ xe điện đến lưu trữ năng lượng tái tạo. Khác với pin lithium-ion truyền thống sử dụng hóa chất dựa trên coban và niken, pin LFP sử dụng lithium iron phosphate (LFP) làm vật liệu cực dương, mang lại sự cân bằng độc đáo giữa an toàn, độ bền và hiệu quả chi phí. Khi các ngành công nghiệp ngày càng chuyển hướng sang các giải pháp năng lượng bền vững, việc hiểu rõ ưu điểm và thách thức của pin LFP trở nên thiết yếu trong việc dự đoán vai trò của chúng trong tương lai của lưu trữ năng lượng.

Ưu điểm của pin lithium sắt photphat

1. Tính năng an toàn được nâng cao

Một trong những ưu điểm nổi bật nhất của pin LFP là tính an toàn vượt trội. Khác với pin nickel-manganese-cobalt (NMC) hoặc nickel-cobalt-aluminum (NCA), pin LFP có tính ổn định cao hơn nhờ cấu trúc hóa học vững chắc. Chúng ít có nguy cơ xảy ra hiện tượng quá nhiệt (thermal runaway), từ đó giảm thiểu rủi ro cháy nổ—một yếu tố quan trọng đối với các ứng dụng như xe điện, lưu trữ năng lượng lưới điện và máy móc công nghiệp. Độ an toàn được nâng cao này khiến pin LFP trở thành lựa chọn ưu tiên cho các ngành công nghiệp nơi độ tin cậy và giảm thiểu rủi ro là yếu tố hàng đầu.

2. Tuổi thọ chu kỳ kéo dài

Một tính năng nổi bật khác của pin LFP là tuổi thọ cao. Pin lithium-ion truyền thống thường có thể chịu được từ 500 đến 1.000 chu kỳ sạc trước khi xảy ra suy giảm đáng kể. Ngược lại, pin LFP thường có thể vượt quá 4.000 chu kỳ sạc mà vẫn duy trì mức hiệu suất cao. Độ bền kéo dài này khiến chúng trở thành lựa chọn lý tưởng cho các ứng dụng yêu cầu lưu trữ năng lượng lâu dài, như xe nâng điện, xe tự hành (AGVs) và hệ thống lưu trữ năng lượng tái tạo.

3. Hiệu quả chi phí và Lợi ích môi trường

Pin LFP có lợi thế chi phí đáng kể so với các loại pin NMC và NCA. Việc không sử dụng các vật liệu đắt đỏ và nhạy cảm về mặt địa chính trị như coban và niken giúp pin LFP trở nên rẻ hơn và ít bị ảnh hưởng bởi các gián đoạn trong chuỗi cung ứng. Ngoài ra, dấu chân môi trường của pin LFP cũng thấp hơn so với các loại pin khác, vì quá trình sản xuất và xử lý cuối đời của chúng tạo ra ít chất thải độc hại hơn. Khả năng tái chế dễ dàng của pin LFP càng làm tăng thêm sức hấp dẫn của chúng như một giải pháp lưu trữ năng lượng bền vững.

Những thách thức hiện tại của pin lithium sắt photphat

1. Độ dày năng lượng thấp hơn

Mặc dù có nhiều ưu điểm, pin LFP thường có mật độ năng lượng thấp hơn so với pin NMC và NCA. Điều này có nghĩa là trong các ứng dụng yêu cầu thiết kế nhỏ gọn và nhẹ—chẳng hạn như trong xe điện hiệu suất cao—pin LFP có thể không phải là lựa chọn ưu tiên. Tuy nhiên, những tiến bộ gần đây trong công nghệ điện cực và kỹ thuật thiết kế gói pin đang giúp thu hẹp khoảng cách này.

2. Hạn chế về hiệu suất trong điều kiện nhiệt độ thấp

Pin LFP thường gặp khó khăn trong điều kiện khí hậu lạnh, nơi hiệu suất của chúng có thể suy giảm đáng kể. Ở nhiệt độ thấp, các phản ứng điện hóa diễn ra chậm hơn, dẫn đến giảm công suất đầu ra và hiệu suất. Điều này có thể là thách thức đối với các ứng dụng ở khu vực có mùa đông khắc nghiệt, đặc biệt là trong ngành xe điện và lưu trữ năng lượng ngoài trời. Nghiên cứu về các công thức điện giải tiên tiến và hệ thống quản lý nhiệt pin đang giúp giảm thiểu những hạn chế này.

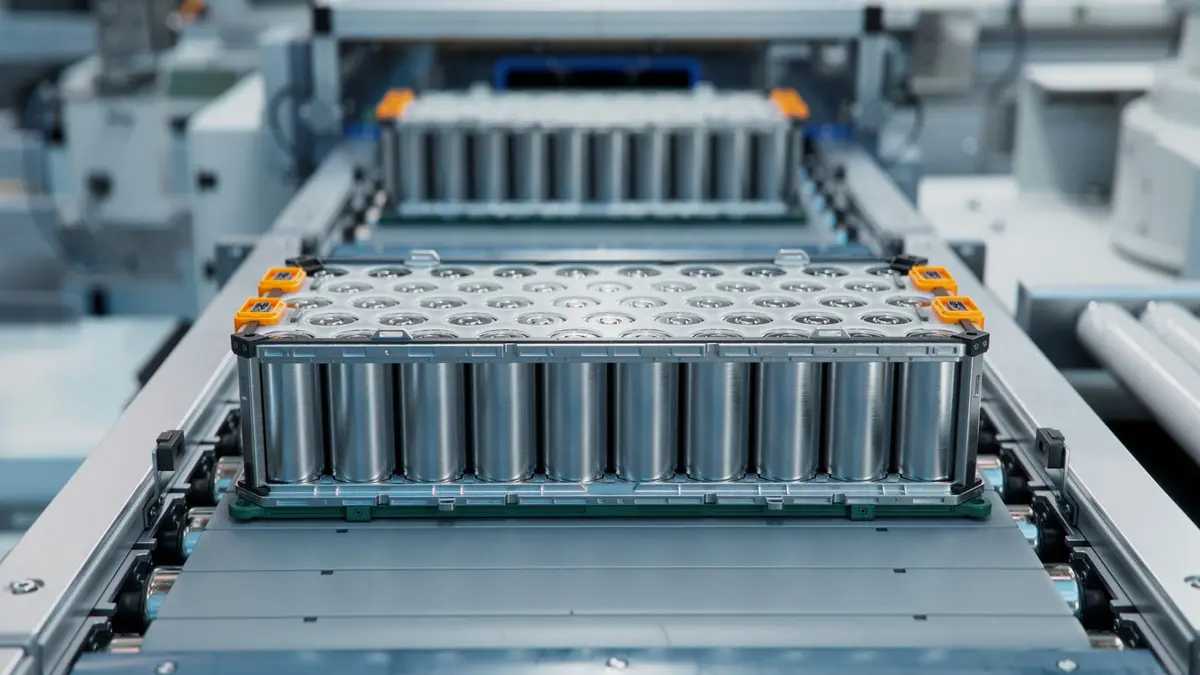

3. Thách thức mở rộng quy mô cho sản xuất hàng loạt

Mặc dù pin LFP đang ngày càng trở nên phổ biến, việc sản xuất quy mô lớn vẫn gặp phải những thách thức về logistics và công nghệ. Hiệu quả sản xuất, tính ổn định của chuỗi cung ứng và sự nhất quán trong kiểm soát chất lượng là những yếu tố quan trọng để đảm bảo pin LFP có thể đáp ứng nhu cầu toàn cầu ngày càng tăng. Đầu tư vào tự động hóa, đổi mới vật liệu và các kỹ thuật sản xuất có thể mở rộng quy mô sẽ là cần thiết để hỗ trợ việc áp dụng rộng rãi công nghệ này.

Triển vọng tương lai: Vượt qua thách thức và mở rộng ứng dụng thị trường

Mặc dù gặp phải những thách thức này, tương lai của pin LFP vẫn rất hứa hẹn. Các nhà nghiên cứu và nhà sản xuất đang liên tục cải thiện mật độ năng lượng thông qua những tiến bộ trong công nghệ nano và các đột phá trong chất điện phân rắn. Ngoài ra, các hệ thống quản lý pin (BMS) mới đang nâng cao khả năng chịu nhiệt và hiệu suất, giúp pin LFP trở thành một lựa chọn khả thi hơn cho nhiều ứng dụng đa dạng.

Trong các ngành công nghiệp như xử lý vật liệu, logistics và lưu trữ năng lượng tái tạo, pin LFP đã chứng minh được giá trị của mình. Việc sử dụng pin LFP trong xe nâng điện, xe golf, xe tự hành (AGV) và máy làm sạch công nghiệp đang ngày càng gia tăng, mang lại cho các doanh nghiệp giải pháp nguồn điện đáng tin cậy, hiệu quả về chi phí và bền vững.

RICHYE: Nhà lãnh đạo đáng tin cậy trong lĩnh vực đổi mới pin lithium

Với tư cách là một chuyên gia pin lithium nhà sản xuất, RICHYE đứng đầu trong lĩnh vực công nghệ pin LFP. Với cam kết về chất lượng, an toàn và hiệu suất, RICHYE Sản xuất pin lithium có độ bền cao, hiệu suất vượt trội và giá cả hợp lý. Dù là cho các ứng dụng công nghiệp, xe điện hay lưu trữ năng lượng tái tạo, pin của RICHYE mang lại độ tin cậy vượt trội và giá trị lâu dài, trở thành lựa chọn đáng tin cậy trong ngành năng lượng toàn cầu.

Phần kết luận

Pin lithium sắt phốt phát (LFP) chắc chắn đang định hình tương lai của lưu trữ năng lượng. Với độ an toàn vượt trội, tuổi thọ kéo dài và lợi thế về chi phí, pin LFP đang trở thành một yếu tố quan trọng trong quá trình chuyển đổi sang các giải pháp năng lượng bền vững. Mặc dù vẫn còn những thách thức như mật độ năng lượng thấp và hiệu suất trong điều kiện thời tiết lạnh, các nghiên cứu và tiến bộ công nghệ đang mở đường cho việc áp dụng rộng rãi hơn. Khi thế giới tiếp tục hướng tới các giải pháp lưu trữ năng lượng sạch và hiệu quả hơn, pin LFP sẽ đóng vai trò thiết yếu trong việc đáp ứng nhu cầu năng lượng toàn cầu.